- What is a thermal oxidizer:

A thermal oxidizer (or thermal incinerator) is a process air pollution control in plants that burn hazardous gases at a high temperature and releasesing them into the atmosphere.

2. Principle thermal incinerator:

Thermal incinerators are used to destroy hazardous air pollutants (HAPs) and volatile organic compounds (VOCs) from industrial exhaust gases. These pollutants are usually hydrocarbon-based and destroyed through combustion, they are oxidized to CO2 và H2O

3. Regenerative Thermal Oxidation:

In industry, there are many technologies to control air pollution, however, Regenerative Thermal Oxidation, RTO is the most widely used technology today.

Rather than allow the clean hot air to exhaust to atmosphere, the RTO unit captures up to 95% of the heat prior to exhausting it to the atmosphere. They are regularly destroying a wide range of pollutants (VOC, H2S, CO, odours and other oxidizable compounds.). MWindow – TMIP offers RTO with high flexible design for many applications.

Our RTO is designed:

– Flow Capacity: From 2.000 to 250.000 Nm3/h

– VOC destruction efficiency: Higher than 99,5 %

– Thermal efficiency: Up to 95%

– Autothermal operation: Starting from 1 g/Nm3.

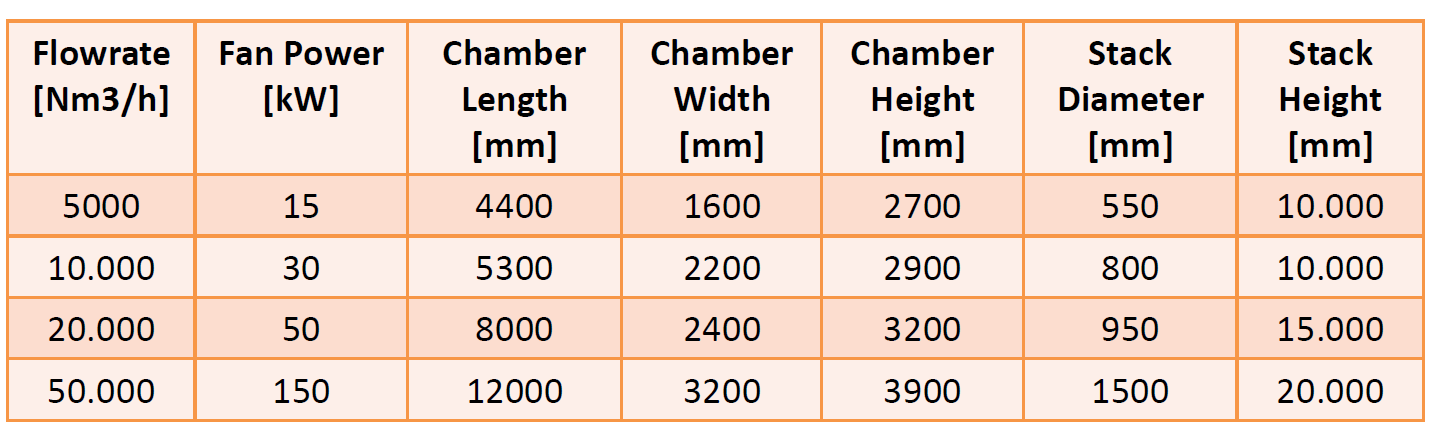

We can provide standardized an customized solutions based on client need: Some standard sizes:

4. Application RTO:

Regenerative Thermal Oxidizers have been installed in a wide range of application, some typical are: Oil & Gas, Pharmaceutical, Chemicals, Resins production, Metallurgical process: Carbon fiber production, Impregnation process, Printing & painting, Semiconductor and coating process generally speaking, Waste water plants.