SOLVENT DISTILLATION PROCESS

Distillation is a process in which a liquid or vapor mixture of two or more substances is separated into its component fractions of desired purity, by the application and removal of heat.

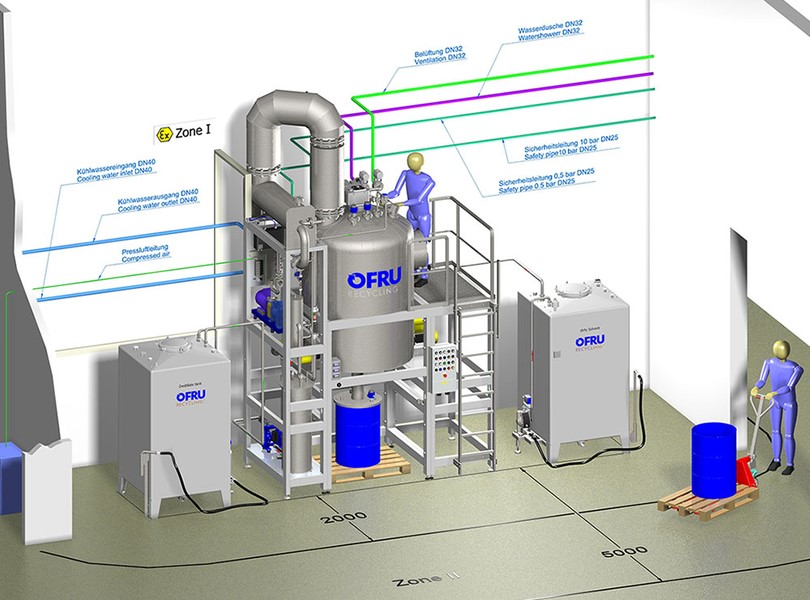

First of all, the contaminated solvent is filled into the distillation plant by hand, pump or vacuum before distillation. In the heating jacket of the distillation plant there is a heat transfer medium which heats the contaminated solvents. The distillation plant can be equipped with steam, hot water, heating water or thermal oil heating. When the solvent boiling temperature is reached, the solvent begins to evaporate. During distillation, solvent vapours flow through a condenser or heat exchanger, where they are liquefied and emerge from the distillation plant as a clean, clear, reusable, reclaimed solvent, called distillate or condensate.

The dirt of the previously contaminated solvent remains in the distillation plant, which can easily be drained of liquid due to its temperature. The distillation plants of the ASC series, for example, have a very efficient agitator with scrapers.

Benefit: After the distillation of the solvents (solvent distillation), time-consuming cleaning work in the distillation plant is no longer necessary. After distillation or solvent distillation, it is recommended to collect the distillation residues in old containers. The solvent residue often flows back into the production process as a raw material and in this respect makes the operation independent of waste management companies.

REUSE OF SOLVENTS

AFTER SOLVENT DISTILLATION

After distillation or solvent distillation, the solvent can be reused for cleaning as it occurs after distillation. With repeated solvent distillation, the mixture may lose “cleaning power” because low boilers evaporate from time to time in the continuous process of solvent distillation. In order to achieve the original solvent quality, experience has shown that after solvent distillation it is sufficient to compensate the losses by fresh solvents in order to achieve a quality.

SOLVENT DISTILLATION PROCESS

Distillation is a process in which a liquid or vapor mixture of two or more substances is separated into its component fractions of desired purity, by the application and removal of heat.

First of all, the contaminated solvent is filled into the distillation plant by hand, pump or vacuum before distillation. In the heating jacket of the distillation plant there is a heat transfer medium which heats the contaminated solvents. The distillation plant can be equipped with steam, hot water, heating water or thermal oil heating. When the solvent boiling temperature is reached, the solvent begins to evaporate. During distillation, solvent vapours flow through a condenser or heat exchanger, where they are liquefied and emerge from the distillation plant as a clean, clear, reusable, reclaimed solvent, called distillate or condensate.

The dirt of the previously contaminated solvent remains in the distillation plant, which can easily be drained of liquid due to its temperature. The distillation plants of the ASC series, for example, have a very efficient agitator with scrapers.

Benefit: After the distillation of the solvents (solvent distillation), time-consuming cleaning work in the distillation plant is no longer necessary. After distillation or solvent distillation, it is recommended to collect the distillation residues in old containers. The solvent residue often flows back into the production process as a raw material and in this respect makes the operation independent of waste management companies.

REUSE OF SOLVENTS

AFTER SOLVENT DISTILLATION

After distillation or solvent distillation, the solvent can be reused for cleaning as it occurs after distillation. With repeated solvent distillation, the mixture may lose “cleaning power” because low boilers evaporate from time to time in the continuous process of solvent distillation. In order to achieve the original solvent quality, experience has shown that after solvent distillation it is sufficient to compensate the losses by fresh solvents in order to achieve a quality.